The manufacturing process of PP woven carry bags begins with the selection of raw materials. Polypropylene (PP), a thermoplastic polymer, is chosen for its strength, resistance to moisture, and recyclability. The PP is sourced responsibly, ensuring that the production of these bags aligns with environmental standards. This initial step is crucial, as it lays the foundation for the quality and sustainability of the final product.

The next phase involves the weaving of the PP fabric. This process is highly technical and requires precision engineering to ensure that the fabric is both strong and lightweight. The PP is extruded into thin strands and woven using advanced looms. The result is a fabric that is not only visually appealing but also incredibly durable, making it an ideal choice for reusable woven bags.

To further enhance the durability and water resistance of the PP woven carry bags, a lamination process is employed. This involves applying a thin layer of material to the fabric, which not only protects the bag from the elements but also adds to its overall strength. The coated PP woven shopping bags can now withstand the rigors of daily use, making them an outstanding choice for consumers who need a reliable and long-lasting bag.

Once the fabric is prepared, it moves on to the cutting and sewing phase. Skilled craftsmen cut the PP woven fabric into the desired bag shapes and sizes. Each piece is then sewn together with precision, ensuring that the seams are strong and the bag maintains its structural integrity. This meticulous attention to detail is what sets PP woven shopping bags apart in terms of quality and longevity.

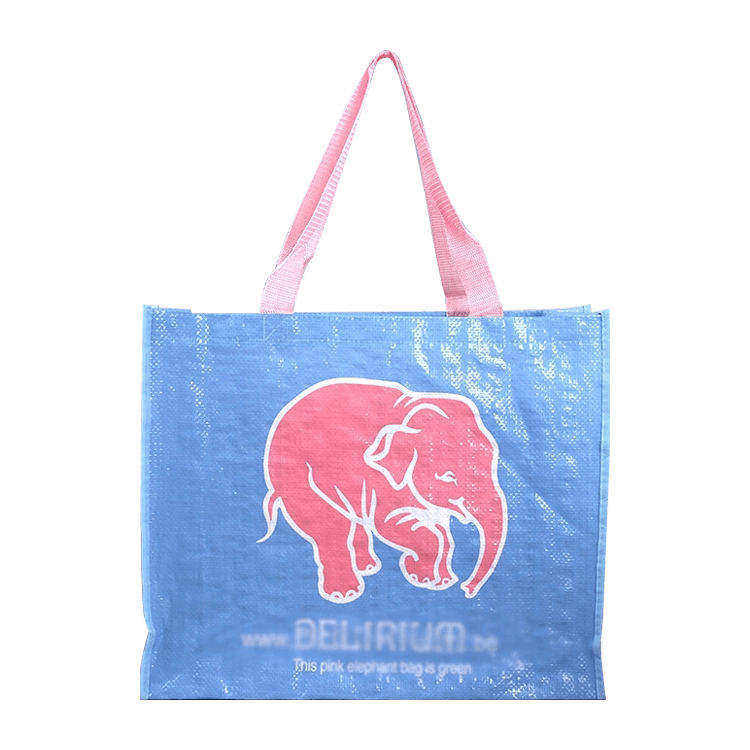

One of the key advantages of PP woven carry bags is their customization potential. Manufacturers can easily add logos, designs, and colors to the bags, catering to the specific needs of clients. This customization process involves high-quality printing techniques that ensure the durability of the print, even with frequent use and exposure to the elements.

Before the PP woven shopping bags are dispatched to customers, they undergo rigorous quality control testing. This includes stress tests to ensure the bags can handle heavy loads, water resistance tests to verify the effectiveness of the lamination, and durability tests to confirm the strength of the seams. Only once a bag passes all these tests is it deemed ready for the market.

As reusable woven bags become increasingly popular, the demand for PP woven carry bags is on the rise. These bags offer a sustainable alternative to single-use plastic bags, reducing waste and promoting a circular economy. Manufacturers are continuously researching and developing new techniques to make PP woven shopping bags even more sustainable, such as using recycled PP or incorporating biodegradable components.

From the selection of raw materials to the final product, each step is carefully crafted to produce a bag that is not only functional but also a symbol of environmental responsibility. As the world moves towards more sustainable practices, PP woven shopping bags are poised to play a significant role in this transition, offering consumers a durable and eco-friendly option for their daily needs.

English

English Español

Español عربى

عربى